Heat Resistant Sheets

Maintaining Strength

Our nickel sheets are designed to withstand elevated temperatures greater than 1,000°F (538°C).

We stock a wide range of nickel alloy sheets that are ideal for elevated-temperature service use. We offer you a multitude of grades and sizes to suit your engineering applications. We also provide processing options where we guillotine your sheets to specific sizes as part of our services.

Uses in Industry

Our heat-resistant nickel alloy sheets perform in the most demanding industrial environments. Our products offer corrosion, creep, and stress rupture resistance while promoting strength at high temperatures. Our sheets find use in various industries, including aerospace, oil & gas, petrochemical and automotive.

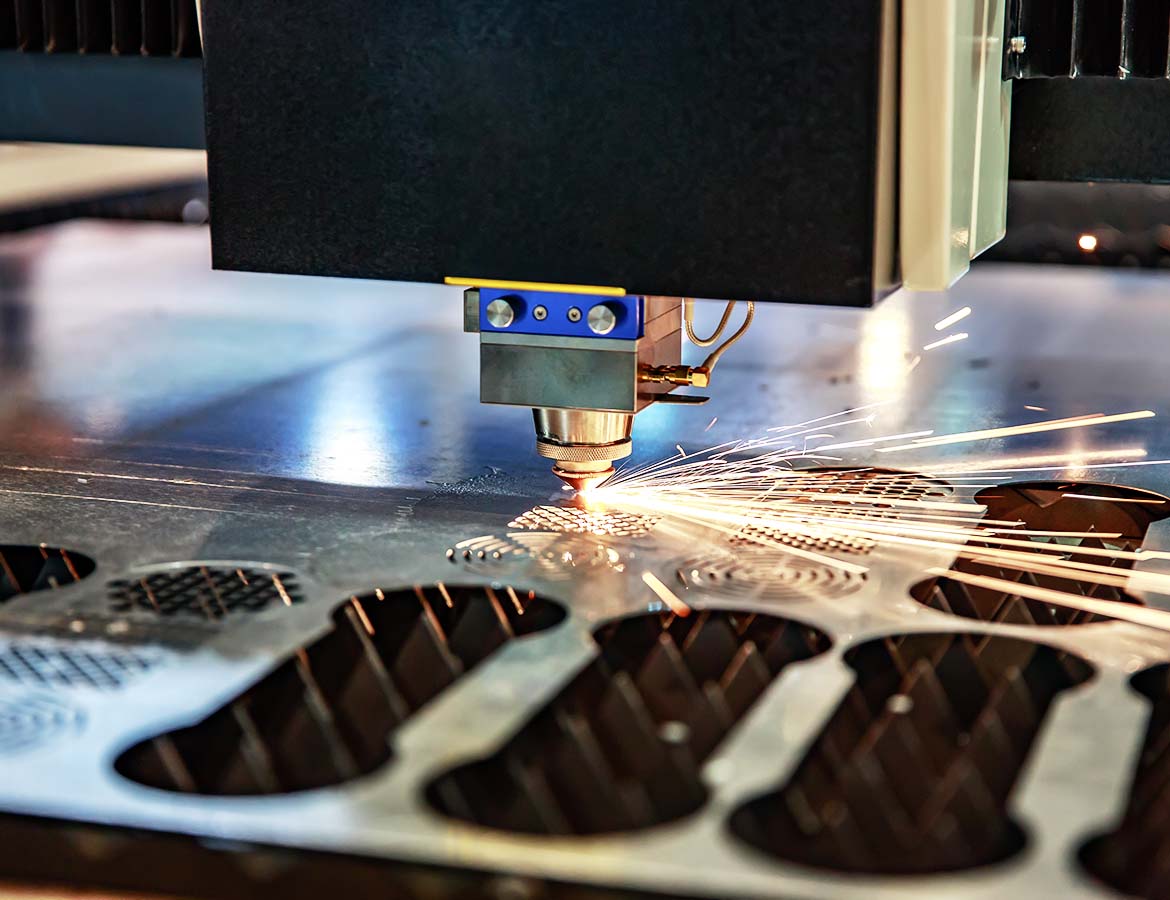

Guillotining Services

We provide in-house guillotine services where we cut your nickel alloy sheets to size. We do this with modern equipment and cut sheets to tight tolerances.

View Range

Sheet used in Gas Turbines

Nickel-based superalloys find frequent use in the production of components for gas turbines.

Nickel is used to manufacture gas turbine products, including blades, vanes, and combustors. Our nickel alloys are highly suitable for high-pressure turbine engineering materials, which offer high-temperature performance capabilities.

Our nickel superalloys offer outstanding high-temperature resistance against creep and stress rupture.

Stock Information

Our nickel alloy sheet stock includes multiple material grades, which offer different performance characteristics and find suitability in various commercial markets.

All our nickel alloy sheet stock carries a unique bar code for total traceability while under our care. Our barcode functionality forms part of our industry-leading bespoke IT platform.

We combine our stock, in-house processing services, and UKAS-accredited metallurgical support services to offer a single supply source for your engineering raw materials.