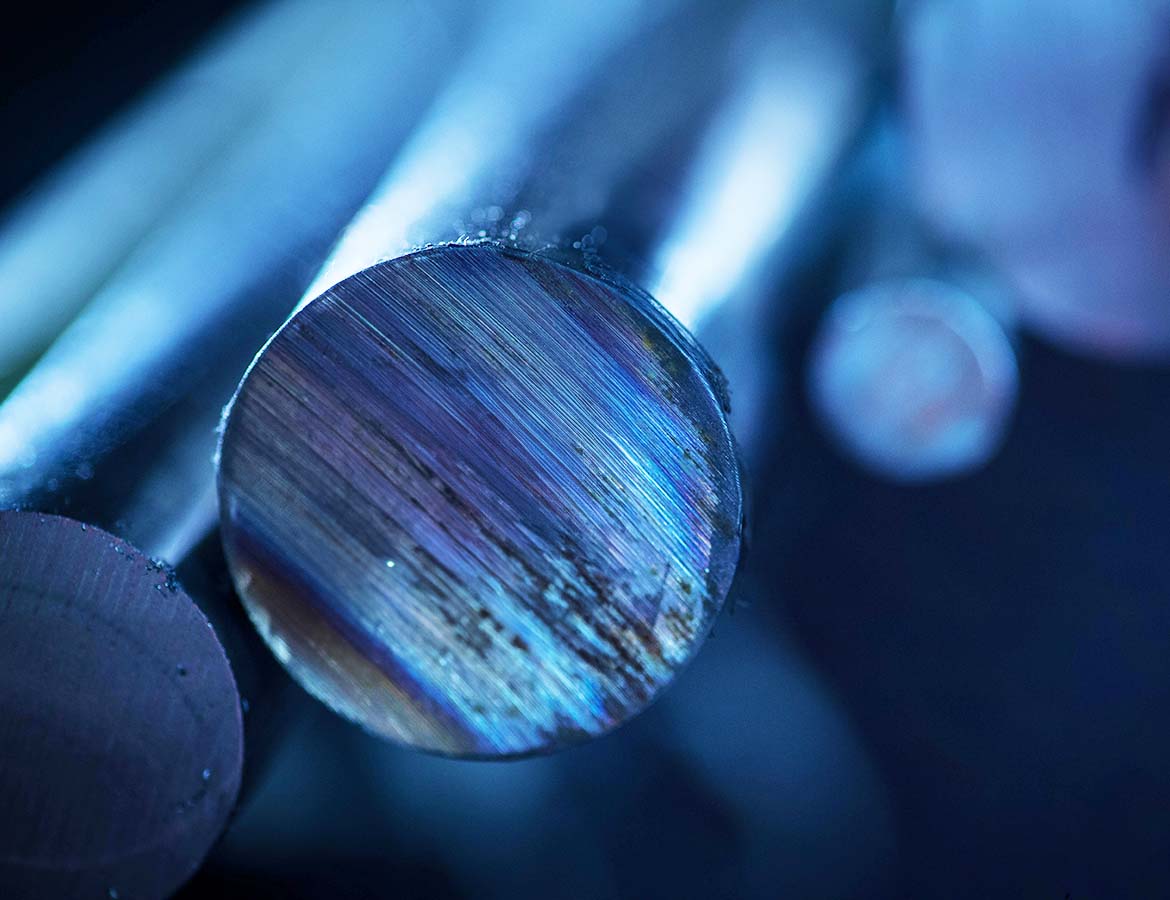

BS S132 Steel Bar

Excellent hardenability.

BS S132 nitriding steel bars contain chrome, molybdenum and vanadium for high mechanical strength.

BS S132 is a nitriding steel alloy that develops a hard, wear-resistant case after surface treatment. The result is a high-tensile alloy highly suitable for applications such as engine shafts, crankshafts and gearboxes. The alloy benefits from excellent hardenability for high core strength, providing a tensile strength of 1,320 - 1,470 MPa. The material is produced by single melting in air, followed by ESR (electroslag refining). However, there is also a vacuum arc-remelted version of this alloy. BS S132 bars and forgings should be subjected to ultrasonic testing where possible, and the material is typically supplied in bright and softened condition.

Commercial Applications

Applications include gearboxes, shafts, turbine/engine parts and motorsport components.

Stock Availability

We stock bars of grade BS S132 in various sizes and closer incremental sizes to suit your individual engineering requirements.

New Testing laboratory Testing laboratory

In 2024, our UKAS Materials Testing Laboratory relocated to a new, expanded, dedicated site in Biggleswade.

Discover- 1.8523

- 40CDV12

- 40CrMoV13-9

- AIR0819

- BS S100

- BS S132

- MSRR6038

- MSRR6119

- Gearboxes

- Shafts

- Turbine engine parts

- Motorsport components

- Excellent hardenability for high core strength

- High mechanical strength

- Hard wear-resistant after surface treatment

- ESR and vacuum arc remelted versions available